Azar Etesal Company’s Pipes for Export

Different Types of Pipes Available for Export

Azar Etesal Company’s Pipes for Export

Pipes for Export with Customization Possibility

Pipes can be customized according to order.

Possibility of Production in Different Sizes

Production in a wide range of diameters is supported.

Possibility of Production in Different Colors

Production of Pipes from 30cm to 6m long

Pipe lengths range from 30cm up to 6 meters.

Production of Pipes in Different Qualities

Different material qualities and grades are available for production.

Normal or Pushfit Coupling

Both normal and Pushfit coupling types are available.

Striated or Simple Surface

Available with both plain and striated finishes.

Production in Different Weight & Thickness

Customizable weight and thickness options for specific needs.

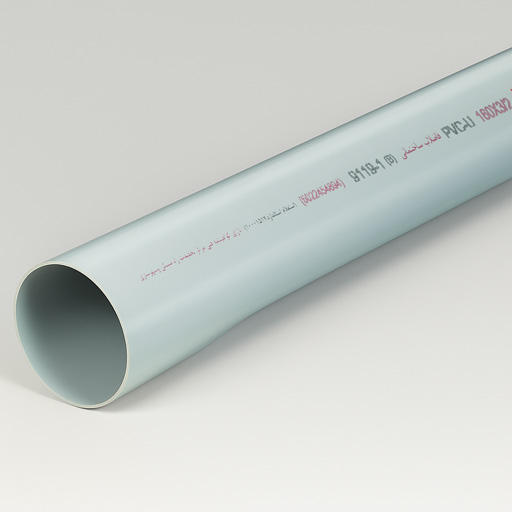

Export-Grade PVC Pipes by Azar-Etessal

Azar-Etessal’s export-grade PVC pipes are manufactured from high-quality raw materials and are renowned for their durability, chemical resistance, and long service life. These pipes are widely used across various applications including residential buildings (for water and sewage systems), industrial operations, and municipal infrastructure. Their superior quality and design make them ideal for diverse climate zones, particularly hot and humid regions where resistance to UV rays, corrosion, and soil pressure is critical. The non-metallic, anti-rust nature of these pipes ensures long-lasting performance in coastal and chemically aggressive environments.

Available Sizes & Standards: Export pipes are produced in 50, 75, 100, 160, 200, 225, 250, and 315 mm diameters, covering the most commonly required sizes for infrastructure projects. These pipes comply with national and international standards, including B and BD classifications (medium and heavy duty), meaning they are suitable for both exposed and underground installation. Their consistent quality—marked by uniform wall thickness, ring stiffness, high impact resistance, and pressure tolerance—makes them an excellent choice for large-scale and long-term use.

Types of Export PVC Pipes & Their Applications

Azar-Etessal manufactures four distinct types of export PVC pipes, each tailored for specific project requirements. Below is an overview of these types and their typical use cases:

Striated (Slotted) PVC Pipes for Export

Striated pipes feature longitudinal external grooves that enhance flow dynamics and reduce surrounding friction. This design improves hydraulic performance and is especially useful in drainage and well systems, where external water movement around the pipe is involved. These pipes are also well-suited for subterranean installations, helping to quickly discharge surface or groundwater. Striated pipes provide excellent performance across construction, industrial, and wastewater projects, particularly where soil compaction or water accumulation is a concern.

Plain-End (Non-Coupled) PVC Pipes for Export

These pipes have straight, plain ends without any built-in socket, making them ideal for glued or mechanical couplings. The main advantage of plain-end pipes is on-site flexibility—they can be easily cut and connected using standard PVC solvent cement or external couplers. This makes them particularly practical for building installations, such as indoor drainage systems or air ducts, where frequent layout changes or multiple branches are needed. They’re also ideal for temporary or modular setups in industrial environments that require adaptability. Despite their simplicity, these pipes deliver strong and reliable performance in residential, industrial, and sewage networks.

Single-Socket (Coupled) PVC Pipes for Export

These pipes are equipped with a built-in socket (female end) on one side and a plain male end on the other, enabling quick, secure, and glue-ready connections. This reduces the need for additional fittings and speeds up installation. Simply insert the male end of one pipe into the socket of the next, apply PVC cement or use sealing rings, and you’re done. Coupled pipes are ideal for long-line systems such as municipal sewage, agricultural irrigation, and large drainage networks, offering high mechanical stability and excellent sealing. Thanks to their quick-install design and strong joint integrity, they are favored for high-volume export projects requiring speed and efficiency.

Push-Fit PVC Pipes for Export

Push-fit pipes are an advanced system featuring a built-in socket with a rubber sealing ring (O-ring) that allows for tool-free, adhesive-free installation. Just push the male end into the socket, and the joint is sealed tight—leak-proof and quick. This system eliminates the need for glue, which means no fumes or curing time, ensuring a clean and efficient installation. Push-fit pipes are highly resistant to shock, movement, and vibration, making them ideal for multi-story buildings, hospitals, hotels, and critical infrastructure. They’re also widely used in municipal sewage systems where reliable sealing and minimal maintenance are essential.

Customization Capabilities for Export Orders

Azar-Etessal’s competitive edge in international markets stems from its high flexibility in custom manufacturing. Export clients can tailor pipe specifications to suit the exact needs of their project. Key customization options include:

- Wide Size Range: Production available in diameters from 50 to 315 mm and beyond, depending on demand.

- Color Variety: Pipes can be manufactured in various colors (grey, white, orange, etc.) to match local standards or improve line identification.

- Custom Lengths: Available in lengths from 30 cm to 6 meters, allowing for both short-length modular use or long segments to minimize joints.

- Multiple Quality Grades: Pipes can be produced in Standard, Class B, or Class BD for different load-bearing and durability requirements.

- Coupling Options: Export clients may choose between plain-end, standard solvent coupling, or push-fit sockets, based on the project’s joining method.

- Surface Finish Options: Smooth or striated outer surfaces can be requested for applications such as general use or specialized drainage.

- Adjustable Weight & Wall Thickness: Pipes can be manufactured in custom weights and wall thicknesses to meet specific project specs (e.g., high traffic loading, deeper burial, or budget-sensitive applications).

All customized products are rigorously tested and certified prior to shipment, ensuring international standard compliance and project-specific reliability.

Bulk Purchasing & Partner Benefits

Azar-Etessal offers direct factory bulk sales with tailored pricing plans for export clients. Large orders benefit from economies of scale, volume discounts, and priority production slots. With a high-capacity extrusion line, the company can fulfill large export volumes within tight deadlines. Products are packed in secure, export-ready formats to prevent any damage during transit. The export support team also assists with customs documentation, compliance, and transport coordination, streamlining your entire procurement process.

By sourcing directly from Azar-Etessal, international contractors and distributors are guaranteed consistent product quality, logistical reliability, and technical support throughout the project lifecycle.

Azar-Etessal’s export-grade PVC pipes are built for demanding construction, industrial, and municipal environments. Backed by modern manufacturing processes, customizability, and strict quality control, these pipes offer a trusted solution for infrastructure development across international markets. Whether you’re building drainage networks, industrial pipelines, or high-rise plumbing systems, trust Azar-Etessal to deliver performance, efficiency, and long-term value—all in one pipe.